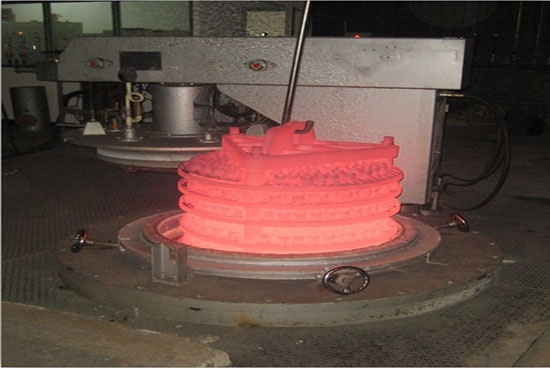

Normalization Process

-

Normalizing heat treatment helps to remove impurities and improve ductility and toughness.

During the normalizing process, material is heated to between 750-980 °C (1320-1796 °F).

The exact heat applied for treatment will vary and is determined based on the amount of carbon content in the metal.

Normalizing is a high-temperature austenitizing heating cycle followed by cooling in still or agitated air that is performed for a variety of reasons but primarily is performed to homogenize the microstructure and remove any segregation or non-uniformities that may exist at the microscopic level

Purpose of the Normalization Process

-

- Grain-structure refinement

- Uniformity of non-uniform structures

- Relieves residual stress

- Improve the mechanical properties of steel

- Improve machinability

Machine Specification

Type : PIT Type

Temperature : 0 °C ~ 1.000 °C Capacity : 1.000 Kg / LOT Heating Method : Electricity Cooling Method : By Still air or slightly agitated air